Rear / Tandem / Trailer Axle Alignment

In order for a vehicle to achieve proper tracking, the wheels must travel parallel to the centerline. All rear axles, including offset axles and axles with different tire spacers or different size tires are set perfectly at 90 degrees to the centerline of the vehicle regardless of whether the chassis is centered over the axle. If the rear axles are not traveling 90 degrees to the centerline of the vehicle, there will be excessive tire wear on the front and rear tires.

Rear / Tandem Axle Alignment

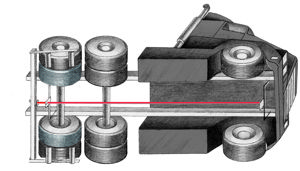

The rear axle alignment is usually thought of as the second most critical tire wearing angle, although the rear axle tracking can be the most costly due to it causing premature tire wear on all of the vehicle’s tires – front and rear. Proper rear axle tracking will also increase fuel mileage since wheel dragging is relieved. The Proven Bee Line self-centering Wheel Cradles assure the correct position of the laser when seated on the cradles in relation to the axle. Wheel Cradles eliminate the need for run-out and raising the vehicle off the floor, allowing the operator to gauge the suspension alignment in its operational position.

"The proven 22000 lets you accurately position your rear axles perpendicular to the vehicle’s centerline, allowing the wheels to travel in a straight line."

With the newly redesigned Bee Line 22000 Portable Rear Axle Aligner, you can take rear axle alignment to your customers’ shops, terminals or wherever they might be located. The 22000 can be used as a stand-alone manual gauging system for tractors and trailers or as a part of our computerized gauging system. The design of the equipment allows the axles to be aligned to the centerline of the vehicle, ensuring maximum tire life and the safest vehicle operation. Self-centering frame gauges and a calibrated laser provide the highest level of accuracy on the market. Tracking error can be diagnosed in less than five minutes. The 22000 is the latest version of our intelligent, time tested design that continues to be the industry benchmark for tractor and trailer axle alignment.

The laser beam is aimed forward in a line identical to the axle’s thrust line and strikes the front target, which measures the amount of axle error from the center line of the vehicle.

Save up to 30% on tire costs and up to 2% on fuel costs.

Trailer Axle Alignment

A properly aligned trailer will travel straight and pull with ease, virtually eliminating excessive or irregular tire wear. The proven Bee Line 22000 Trailer Axle Aligner lets you accurately position your axles perpendicular to the trailer's centerline (setting track), allowing the wheels to travel in a straight line.

» Significantly reduce the leading cause of tire wear when you accurately position your rear axles perpendicular to the trailer's centerline allowing the wheels to travel in a straight line.

» Innovative product design features eliminate the need to raise the trailer off the floor, enabling you to quickly gauge the suspension alignment in its operational position using "live" readings.

» Improve customer satisfaction and make a positive impact on axle mounting cycle time.

» Available in a full cabinet system or a portable laptop system.

View our videos on set-up, gauging, tramming and calibration to see how quick and easy this highly accurate system will work for you!Have a Question?

We’re here to help. Head over to our question hub and get answers direct from our experts!

Ask a Question